While in the process of checking the packing around the propeller shaft with the transmission in neutral I was able to rotated the flexible coupling by hand to see if there was dripping. Sure enough there was a lot of dripping (one per second). Next I unlocked the locking nut closest to the hose clamps and then I tightened the stuffing box nut by 3/4 of a turn.

Click here for pictures of stuffing box

Then I rotated the shaft a few turns by pushing on the flexible coupling. There was no more water dripping or maybe just one drip every twenty seconds. Then I turned the shaft in the other direction and noted that I could turn the coupling about 15 degrees before the propeller shaft started to turn.

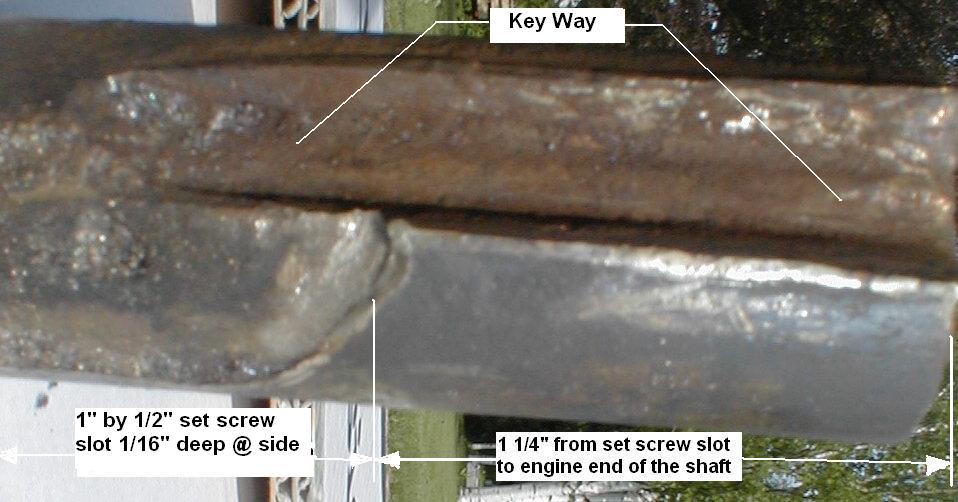

There are two flats on the prop shaft and they are 180 degrees apart and pretty much where the two set screw are.

The two set screws are rusted in place and have a square 7/16" head. About the only real way to get at these is by using a socket wrench with a two foot extension, but there are not too many 4 point sockets in this world. The local hardware store had 12 point sockets, but it would not fit. The local car mechanic did have an 8 point socket for my 3/8" drive. I also ordered an 8 pointer from the local Craftsman retailer. Would have liked to get a four point socket, but even the two farm implement dealers in town did not have them.

The Federal Flexible Couplings are on page 6 and 7 of the Acrobat Reader and page 26 and 27 of the document.

I suspect that the problem with this amount of backlash is that the shaft is no longer being held very well. The coupling needs to be replaced promptly, and one needs to avoid driving hard in reverse as it may just suck the prop shaft right out of the coupling. Until the prop hits the skeg or the zinc hit the strut.

After I cleaned up the shaft I noticed that there is one half of a set screw marks visible on both flats of the shaft. This would indicate that the shaft has already started moving toward the packing. It turns out that the flat is about one inch from end to end and does not go to the end of the shaft. This makes the set screws sit in a pocket and makes it very difficult for the shaft to slip out of the coupling, a great feature.

For a couple of days I concentrated on tightening the two set screws till the backlash goes away. I tried Blaster, Liquid wrench, lots of tapping with the ball peen hammer, and alternate plus an minus torque using a two foot lever arm and a two foot extension for two hours and they never budged. I gave up and took it to the marina and they pulled the boat out.

The guys at the marina never did get the set screws out, but they finally snapped. Then they tried to drill them out, but to no avail as they are case hardened steel. So we ended up cutting the shaft off in that ¼" space between the coupling hub and the packing spud nut using a Milwaukee Sawzall. The four long bolts holding the coupling to the spider at the transmission came off rather easily. We found the key in the hub that was pretty badly chewed up and a keyway that was really worn out. The set screws were working their way to the front of the shaft but still had a ½" to go so we probably could have motored a long time yet before the shaft would have come out of the coupling.

If I would have had a dripless shaft seal I would have never noticed the problem. During the travels around town in search of the four point socket I ran into a guy who lost a prop and shaft last summer on his friends sailboat and when he went down and saw the water spout he also saw a tapered plug tie wrapped right next to the now busted coupling. There is something to be learned from the Marion to Bermuda race requirements. Thinking about it some more I came to the realization that there is only about 1/4" of shaft showing between the coupling and the packing spud nut, so how could I ever stuff a tapered pin into the packing nut? The best I could think of is a tapered flat piece of wood to jam in between the coupling and the packing spud hex nut.

The marina ordered a new shaft, coupling, and cutlass. The shafts are stainless now rather than bronze. We could not get the old shaft out without removing the cutless bearing as it just was not offset enough to the starboard side so that it could clear the skeg.